What Required for Hardware in the Loop System Project National Instruments

All NI real-time hardware platforms are based on a common architecture, which means that programs that yous write with LabVIEW Real-Time will work beyond different NI hardware with only small modifications, or without modifications. Specifically, each hardware platform features off-the-shelf calculating components including a processor, RAM, nonvolatile storage, and an I/O bus interface. Some hardware platforms feature a user-programmable FPGA that you can plan using the LabVIEW FPGA Module.

PXI (PCI Extensions for Instrumentation)

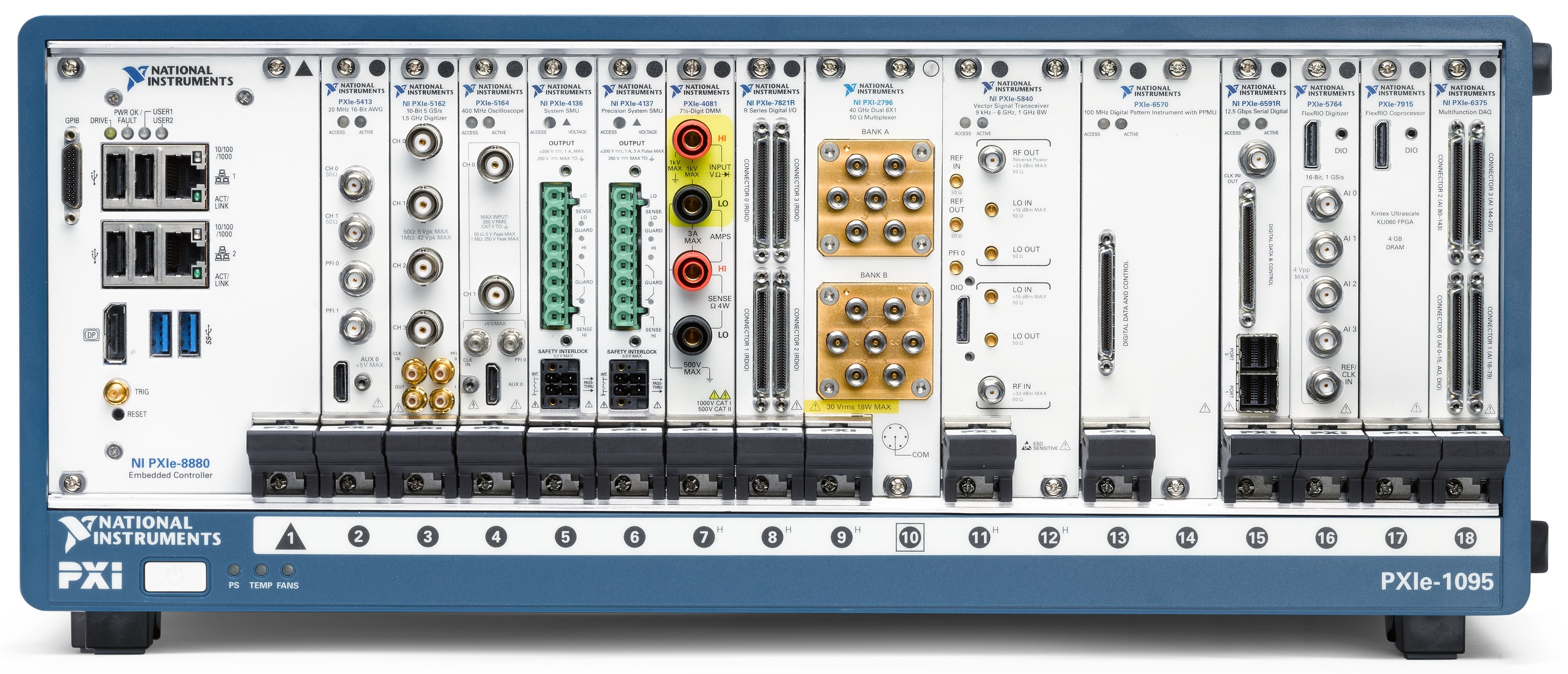

The industry-standard PXI platform consists of a rugged chassis with integrated timing and triggering lines, an embedded controller, and plug-in I/O modules. Serial, USB, Gigabit Ethernet, and GPIB ports are too congenital into the controller. PXI real-time hardware can exist programmed using either LabVIEW Real-Fourth dimension or LabWindows/CVI Real-Fourth dimension.

If you have an existing PXI controller running Windows that you would like to change to a existent-time controller, you can purchase a LabVIEW Real-Fourth dimension Deployment License to convert your controller, or even prepare a dual-boot system.

You can gather your ain PXI real-time system including controller, chassis, I/O modules, and software using the online PXI Advisor.

Effigy 4. PXI hardware provides a rugged, high-operation option for your real-time projects.

NI PXI hardware is often used for high-performance real-time systems such equally hardware-in-the-loop testing of electronic control units and vibration assay for machine-status monitoring applications. When using a real-time PXI organisation, your applications have access to advanced timing and synchronization hardware features that simplify precise I/O triggering and multimodule synchronization.

CompactRIO

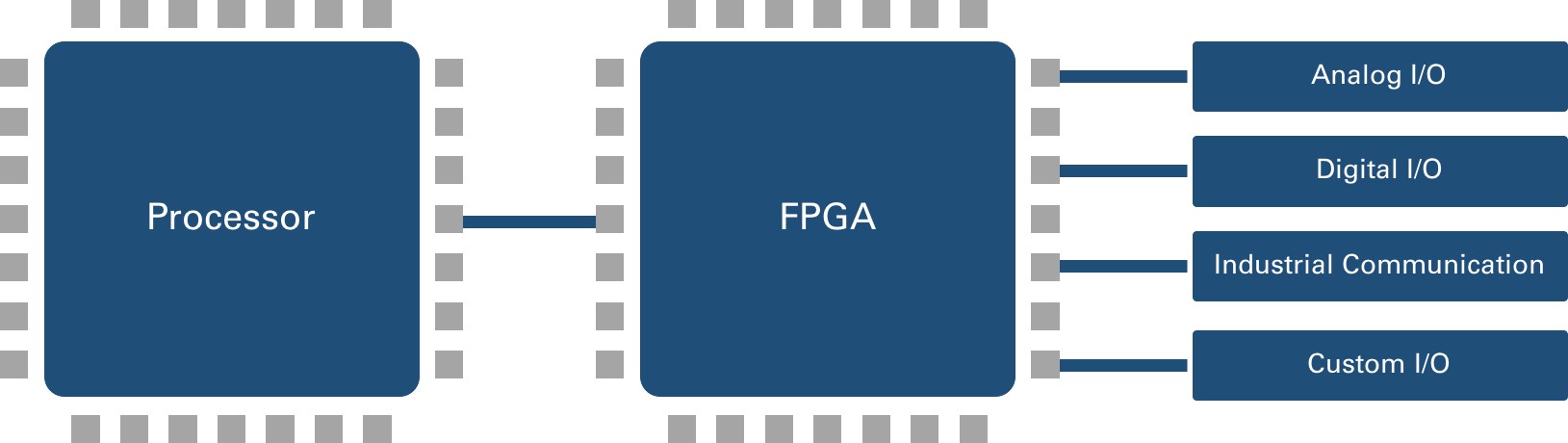

CompactRIO combines a existent-time processor, an FPGA, and C Serial I/O modules, and comes in both packed and board-level form factors. In add-on, serial, USB, and Ethernet ports are built into the controller.

You tin can get together your own CompactRIO system including controller, I/O modules, and software using the online CompactRIO Advisor.

Figure 5. Packaged CompactRIO controllers provide a flexible, rugged, and portable option for real-time applications.

Y'all can program the processor on CompactRIO controllers using LabVIEW Existent-Time or your C/C++ development tool of choice. You can also develop FPGA code using LabVIEW FPGA. To access IO data on the processor, y'all tin can apply the NI-DAQmx API, NI'south best-in-form programming API for measurements, or NI Scan Engine. Culling, you can access data direct from the FPGA with LabVIEW FPGA.

Figure 6. CompactRIO'south heterogeneous compages features a existent-time processor, reconfigurable FPGA, and I/O.

CompactRIO hardware is often used for industrial applications including status monitoring, hardware-in-the-loop test, concrete systems test, and auto control.

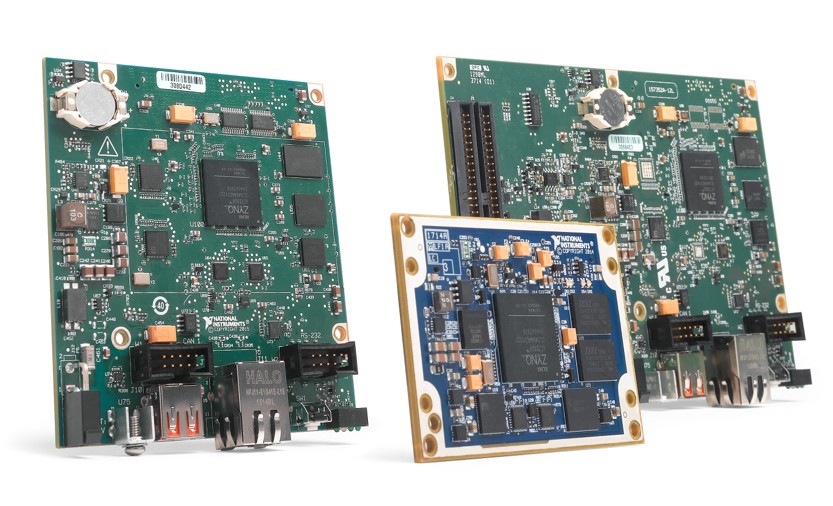

CompactRIO board-level controllers, such as CompactRIO Single-Lath Controllers (sbRIO), have the same compages every bit packaged CompactRIO controllers, just come up without rugged packaging, and have a smaller grade gene.

Effigy 7. CompactRIO board-level controllers characteristic the same compages as packaged CompactRIO controllers, but in a smaller form factor.

High-volume applications that require flexibility, reliability, and high performance tin can benefit from CompactRIO Single-Lath Controllers or System On Modules.

Industrial Controller

NI Industrial Controllers are high-performance, fanless industrial computers that offering the highest level of processing power and connectivity for automatic image processing, data acquisition, and control applications in extreme environments. These controllers feature up to a two.2 GHz Intel Core i7 dual-cadre processor, 8 GB DDR3 RAM, 64 GB storage in a rugged design with no moving parts, and an IP rating up to IP67. A Kintex-7 FPGA improves organisation performance past providing custom I/O timing, synchronization, command, and image co-processing.

Figure 8. Industrial controllers feature high processing ability and connectivity ideal for vision systems.

NI Industrial Controllers requite you lot the platonic connectivity for communication and synchronization to Time Sensitive Networking (TSN)-enabled CompactDAQ chassis, EtherCAT and Ethernet CompactRIO chassis, EtherCAT motion drives, GigE Vision and USB3 Vision cameras, and other automation equipment. In add-on, this controller has onboard ISO, TTL, and differential digital I/O, so it can perform synchronization and control tasks without additional tethered I/O.

0 Response to "What Required for Hardware in the Loop System Project National Instruments"

Post a Comment